Processing

AFTER PROCESS

TRANSPAPER

Capacity

Avg output / day / table : 600 prs

Capacity TP / Day : 3,600 prs/day

Capacity TP / Month : 88,200 prs

SPRAY

Capacity

PAINTING

Capacity

LABATORY & MOLD SHOP

Laboratory Machine List

To ensure best quality and prevent any problem, we test everything that’s needed for injection materials within our company before sending to customers.

2. Tensile Machine(Cometech QC-548)

3. Din Abrassion Machine

4. Viscosity Machine(Brookeld LV)

5. Rossex Machine(GT-7011-R, GT-7006-E)

6. Weight(Quatro)

7. Specic Gravity(EW-200SG)

8. Heat (Thermo Scientic Cimarec)

9. Stir(Thermo Scientic Cimarec)

10. UV Light Test Machine (GT-7035-UA)

11. Suntest Cps+ (Altas)

12. Hardness Shore A (Asker JIS K 6253)

13. Hardness Shore D (Teclock GS-702N)

Mold Shop Machine List

In order to give quick service, we use our mold shop for any defects on the mold during process.

- Sandblast Machine – 2 pcs

- Argon Machine (Hobart Tigwave 350 AC/DC)

- Drilling Machine (Samchully STD-40, Krisbow KW1500539)

- Ragum Machine (Wacheon)

SUSTAINABILITY

Regarding Sustainability, PT. KORIN TECHNOMIC is developing on two aspects : Bio-based Raw Material and Recycle Material

BIO-BASED MATERIALS

We provide options for materials that are high bio based contents

LUBRIZOL [PEARLTHANE ECO 12T95]

Bio Based Content : 32%

Covestro Desmopan EC33085AU DPS301

Bio Based Content : 39%

Covestro Desmopan EC33090AU DPS301

Bio Based Content : 36%

Covestro Desmopan EC33095AU DPS301 –

Bio Based Content : 35%

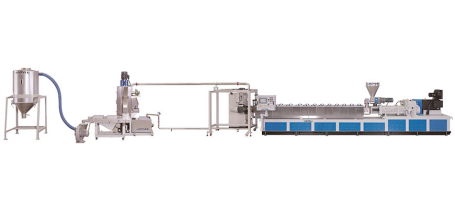

Recycle Extruder

Due to high price bio-based Materials, PT. KORIN started Recycle Extruding Process : KORINECO

Benefits of Recycle Extruder :

Stable state of Recycle Material ->

- Can use more % of Recycle Material

- Stable Color of Recycle Material

- Quality of Recycle Material can be tested